A 2017 issue of Supply Chain Management Review featured new research from Pennsylvania State University on how “we tend to overlook the soft side, which is trust, reciprocity [and] interpersonal relationships” in business supply chains. Trust, according to the research, has a high impact on how well a supply chain functions. Additionally, the study found that “trust reduces opportunistic behavior only when both sides have similar levels of trust.”

For people in the organic textiles business, balancing this trust with certification — which requires continuous scrutiny of all supply chain participants — is a challenge.

A delicate but initial step is setting up a supply chain under the Global Organic Textile Standard (GOTS), the leading organic certification for fibers and textiles. An international supplier unfamiliar with GOTS or its specific requirements might view the mandatory recordkeeping, inspections and testing as a questioning of their trustworthiness.

Yet despite the overwhelming initiation into its strict rules, GOTS certification also offers an opportunity to establish a productive partnership between suppliers and buyers. The following recommendations offer ways to use the standards to cultivate trust while also ensuring the integrity of the whole supply chain.

Understand the agricultural process

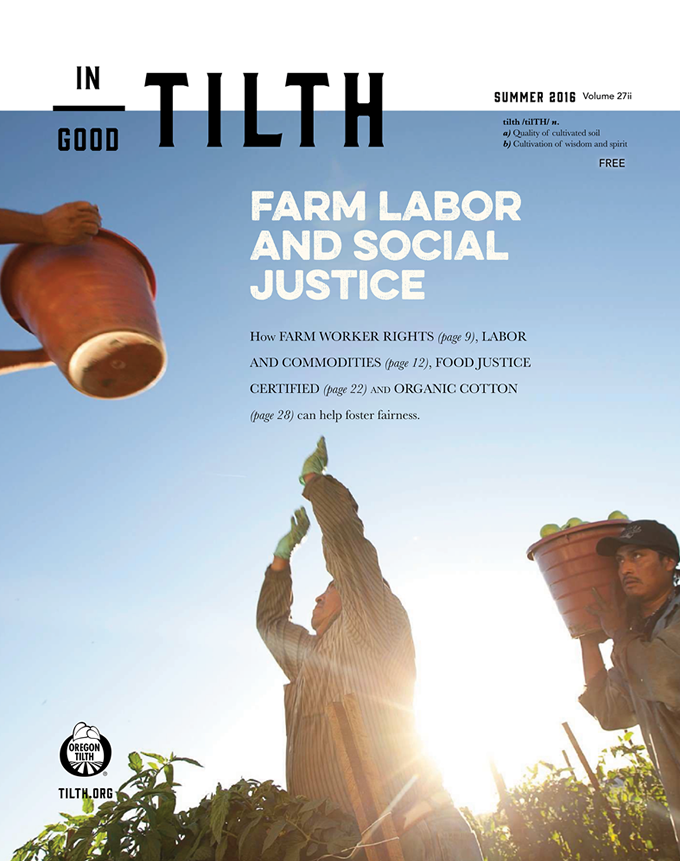

All supply chain participants benefit from understanding the farming behind fibers and textiles. Farm production is highly unpredictable and variable. Buyers and others further down the chain often don’t understand (or embrace) why a fiber varies from harvest to harvest. For them, a chief concern is consistency of the agricultural product. Yet it is nearly impossible for something coming off the farm to perfectly match a list of characteristics on paper.

While costly and time-consuming, taking a hands-on approach with farmers in your supply chain allows for clearer communication on why a crop is the way it is. Together, suppliers and buyers can troubleshoot situations like unanticipated drought, pest problems or grazing issues. A mutual appreciation of what is desired (by the buyer) and how to meet the goal (by the farmer and suppliers) will lead to a better, more reliable supply.

Set expectations and boundaries on day one

There are absolutes in certification. If these can’t be met, it should be a dealbreaker for anyone looking to build their supply chain. For example, if transaction certificates or other sources of verification for product claims are unavailable, then look elsewhere. Is someone unwilling to provide access to documentation that backs up the certification? Giant red flag. The bottom line? Never make a decision or purchase without obtaining admissible certificates and records that verify a product.

Verification is not just access to pieces of paper. Your suppliers must also buy into building and supporting quality control systems that act as certification safeguards. For instance, it’s vital to have protocols in place for conducting regular product testing, particularly with new sources. If a supplier is against setting up quality assurance controls, you need to move on.

Collaborate on risk assessments to create sensible testing protocols

Furthermore, the development of a testing protocol can help confirm the legitimacy and handling of at-risk supplies. Testing varies from country to country, lab to lab. And while GMO tests use different methodologies with varied results, a pesticide residue test mostly offers a straightforward yes (positive) or no (negative) result on the presence of a prohibited substance.

Testing is a critical tool — for certifiers and companies — to learn if a product is meeting certain aspects of the certification standards. Implementing a testing protocol is sensible. Determine when and where testing will be appropriate and have maximum impact. Within GOTS, residue parameter tests are required. Timing of the tests is critical. For example, checking and testing wool before it is washed at the scouring mill is the best opportunity to catch an issue.

Buyers, suppliers, growers and processors must collaborate to determine risks, together. Think of it this way: a farmer will know if a certain grazing location is at higher risk due to a boundary farm’s application of pesticides. The buyer, supplier and farmer should all be aware of the issue. A testing protocol can be applied to assess if preventive grazing rotation strategies are working.

Owning the risks together is a radically different way to use testing as a tool. And this can help avoid creating a culture of isolation and distrust between supply chain participants.