Batchat is a tiny village in the eastern Indian state of Orissa. From the district headquarters of Bhawanipatna, it takes about two hours by car on single-lane roads to the hills and then on dirt tracks into the forest until you reach Batchat: a cluster of small, neatly built adobe brick houses. Thirty two families live here and half of them grow cotton. One of the farmers is Tarun Naik. He lives with his wife Kamalini, their two kids, his mother and three of his siblings in just two rooms. But with the money he is making with organic cotton he’ll be able to afford a one-room extension to the house. He’s already bought the bricks which are stacked up against the rear wall. The family owns two acres of land, and apart from the bullock- drawn plough used to prepare the seed bed, all tasks are done by hand. Timing is dictated by the arrival of the monsoon.

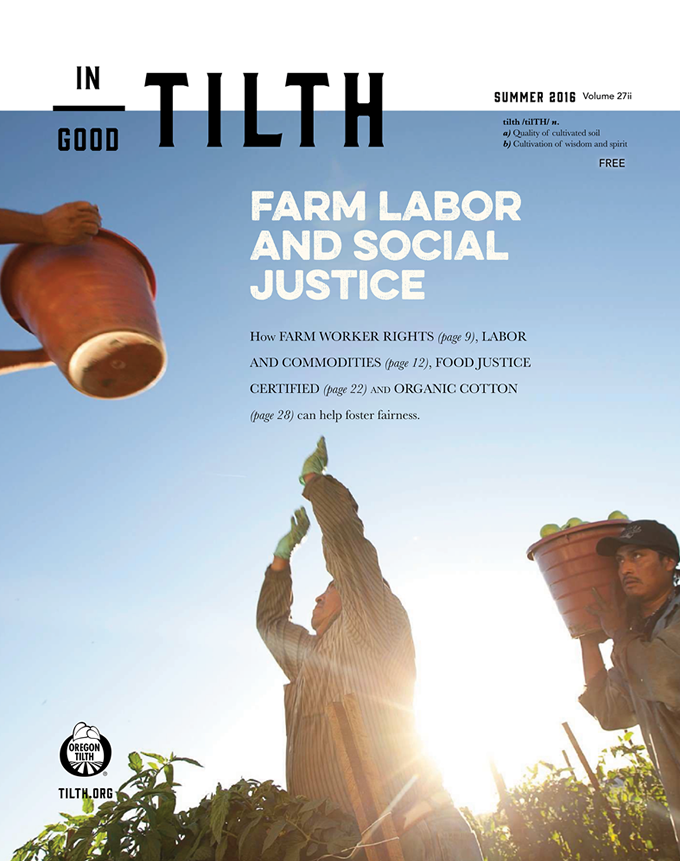

In Orissa and most of the Indian cotton belt, there is not enough water for irrigation. To plant the seed, farmers like Tarun team up with neighbors. A small indentation is made and filled with compost into which the farmers place two cotton seeds (in case one does not germinate). If there is enough moisture, it takes about a week until the first green sprouts can be seen. Five weeks later, the plants have grown considerably. By heaping soil around the stem, the farmers provide extra support to the cotton plants, and they create a furrow between the rows into which lentils are sown. The lentil plants provide nitrogen for the cotton and an additional income. With enough rain at the right time, the cotton can be hand-picked between November and January. Then the dried-off cotton and lentil plants are collected, manually cut into small pieces, mixed with straw and cow dung, and left to ferment in a pit for three months so that the organic compost is ready just in time for the next round of seeding. Tarun and the other farmers in Batchat switched to organic farming in 2013, with the help of a non-governmental organization (NGO) that trained them in organic farming methods. Until then they had farmed cotton conventionally and most of them were deeply indebted. At the time, Tarun owed so much money that he was about to lose his land and the family’s two cows. In remote areas like this part of Orissa, farmers have no choice as to where to buy their seed. In the nearest town there is only one seed merchant who supplies seeds, fertilizer and pesticides. Farmers like Tarun are so poor that they buy everything on credit against the next cotton harvest with an interest rate of around 60 percent. If cotton prices are low and the yields are bad, farmers can end up making a loss, further increasing the debt.

Today, 95 percent of the cotton grown in India is Bt hybrid cotton, but yields “are way below the global average of 2,700kg/hectare,” says the Indian magazine Outlook in a recent article. Companies like Monsanto promise up to 20 percent higher yields, but only under ideal conditions which include sufficient water supply (in India almost impossible to achieve without irrigation) and double the amount of fertilizer. This means significantly higher input costs (seeds and agrochemicals) for Bt cotton, and–as most Indian farmers have to buy on credit–just one bad harvest can lead into a downward spiral of debt. Since the late 1990s, more than 300,000 Indian farmers have committed suicide, most of them did so because of the debts the families were facing. The suicide rate is highest in what’s known as the “cotton belt.” Bt cotton didn’t cause the rise in suicides, but it is certainly a big part of the problem.

Organic cotton is part of the solution. Farmers don’t need to buy fertilizer. They make their own with manure, composting and mulching. Neem leaves or a concoction of cow urine, palm sugar and bitter leaves (“anything a goat won’t eat”) are cheap and efficient organic pesticides. And there are NGOs running organic farming training schemes, assisting with certification, marketing and helping farmers to pre-finance and buy seeds in bulk — none of which would be possible without the higher prices paid for organic cotton. It’s the organic premium that has given farmers like Tarun the chance to turn their lives around. He can feed his family. His debt is paid. His daughter goes to school, and he can think about building that one-room extension.

The biggest hazard for organic cotton farmers is the risk of GM contamination, not just through cross-pollination but through contaminated seeds. In organic agriculture only untreated seeds can be used, but because (compared to Bt cotton) there is so little demand for conventional, let alone organic seed, few seed companies are willing to produce non-GM hybrid seeds at all. And if they do, contamination cannot be excluded at any stage of the process.

In Orissa, farmers, scientists from the organic agricultural research organization from Switzerland, FIBL and agronomists from the agricultural university in the Indian state of Karnataka are working on a solution: open-pollinated cotton seeds which the farmers could save for the following year after their cotton has been ginned.

There are over 700 indigenous or “desi” cotton varieties in India.

From the 50 or so varieties that are being grown on a small NGO-run research farm in Orissa, seven have been selected for field trials, and the scientists hope that within four to five years an open-pollinated cotton variety providing decent yields and staple length, well adapted to growing conditions in Orissa, will be available to organic growers there. Two of the varieties are what’s called “diploids,” which means they cannot be cross-pollinated by GM cotton.

In Kutch, a traditional cotton growing region in the western Indian state of Gujarat, farmers are rediscovering a “desi” variety called “Kala cotton.”

The landscape here is flat and arid even though the coast and the Arabian Sea are only about 30 miles to the south. Some three hours drive to the west is Makhel, home to 150 farming families. Twenty-four farmers are members of a co-operative growing organic Kala cotton.

The 56-year old Kalyarbhai Nathubhai Madhri was one of the first to get organic certification for the 50 acres of land he owns. Clad in white with a huge turban, he sits cross-legged on a charpoi, a traditional Indian day-bed. A tall palm provides shade for the courtyard, its feathery leaves fanning in the breeze. It’s January, but in mid-afternoon the temperatures climb to the high eighties, in summer this part of India gets plenty of days with 120°F. “If you were to invent a fiber for our region, it would be like Kala cotton,” he says. “Until the early ’70s everyone grew Kala, and the women spun it and wove it into cloth. All our clothes were made from it.” Kala is a short staple cotton variety perfectly adapted to the conditions of this part of Gujarat. It needs little water and is disease and pest resistant. It is not easy to spin and weave, but it can be made into very durable, airy and water-repellent fabrics. For centuries, Kala cotton canvas was used as protective cover for goods transported by road or sea. The fibers are strong enough to make into ropes as well as into very delicate, thin and soft fabrics. The multiple layers of traditional Kala cotton garments for women and men are airy and light, but provide excellent protection against dust. The fiber is naturally very white in color, which means it reflects rather than absorbs heat, and the slight water-repellent quality enhances the cooling effect sweat has on the skin. “When you work in the fields, you are much more comfortable in Kala cotton clothes than in what we now buy. They mix polyester with cotton, it’s awful, you sweat and it stinks,” says Kalyarbhai Madhri. But clothes made from artificial fibers and cotton mixes are readily available in any market, and they are cheap. “We’d all wear Kala cotton if it wasn’t so expensive,” says Madhri.

In Bhuj as well, it’s an NGO which is trying to revive the Kala cotton tradition. The organization pays good prices to farmers who grow Kala cotton, and it helps with organic certification. It works with artisan spinners and weavers, from training to quality control, to product development and marketing. But it’s an uphill struggle in a market where, compared to synthetic fibers, natural materials like cotton have become niche, and that niche is dominated by Bt cotton.

But things might be about to change in India. “Failure of Bt cotton forces gov(ernmen)t to promote native seeds. Agriculture Ministry decided to revive cultivation of indigenous varieties of cotton,” read the headline in the Indian paper, the Business Standard, on April 5. If the Indian government were to put money behind this decision it would signify a policy turn which could benefit millions of farmers. But it would take a lot of money–not just for research purposes to find regionally well-adapted, high- yielding open-pollinated cotton varieties. The biggest immediate problem is that there are hardly any seeds of the indigenous varieties left. When Indian scientists (together with the Swiss FIBL specialists) started the cotton breeding project in Orissa, they often had a hard time finding even just a handful of seeds of any single variety.