It’s one thing to grow organic fruits and vegetables. Farmers know how. It’s another to get those products into the hands of customers who increasingly want them. That’s where distributors — and all of their magic, planning and logistics — come in.

Strolling through one of Portland’s many farmers markets on a sunny fall morning is a delight. Trees on Portland State University’s campus form a brilliant backdrop for the stalls of more than 100 vendors. The scent of coffee and freshly baked goods fills the air. And the display of cheeses, bread, cured and fresh meats, fish, apples, pears, berries and vegetables speaks to the bounty of agriculture in the Pacific Northwest. Most of the produce is organic, and the Oregon Tilth logo is often prominently displayed.

At the back of the “Gathering Together” farm stand, produce cartons carry the LADYBUG logo, signifying one of several Organically Grown Company (OGC) brands created to showcase certified organic family farms. The brands make up just a portion of OGC’s products and services. It’s the largest organic distributor in the Pacific Northwest.

OGC has an illustrious history. Back in 1978, as the organic farming movement picked up steam all along the west coast, a group of young farmers realized they were competing at the local farmers market every week and not making any money. Working together, coordinating cropping plans and helping each other out sounded like a good idea. By 1982 they’d formed a co-operative, which grew into the employer- and grower-owned OGC of today. Ninety-five percent of the produce OGC sells to its roughly 500 retail grocery and retail chains, restaurants, food-buying clubs and juice bars is organic. Only a small part of the produce goes into wholesale.

The growers benefit from “40 years of produce market intelligence,” said Kimberlee Chambers, OGC’s supply chain and sustainability program manager, speaking from the company’s offices next to its 120,000-square-foot Portland warehouse (OGC’s headquarters is in Eugene). OGC buyers take pride in keeping in touch with farmers from big farms and small. Regardless of the farm size and the crops, buyers need to think on their feet, even at 5 a.m.

“There’s the farmer who calls up and says, ‘Don’t send the truck, the laborers haven’t shown up, the produce is still in the field,’” said Chambers. “There are weather events like flash floods or ice that make roads suddenly impassable, or ports closed due to a strike.”

Buyers also share information, help with health and safety compliance or tackle really big issues such as succession planning.

What lies ahead for OGC? “We want to keep responsive,” said Chambers. Safeguarding the future of small and midscale growers, online shopping and working towards carbon neutrality are just some of the challenges.

Bridges Organic Produce

From his office in a clapboard house on Portland’s east side, Ben Johnson conducts the business of Bridges Organic Produce, the distribution company he founded 15 years ago. Originally from Kentucky, he grew up just 40 miles down the road from the farm of Wendell Berry, the novelist and poet. Reading Berry’s work influenced what he wanted to do in life: work with produce and for the benefit of farmers.

Johnson moved to the Pacific Northwest, where his wife grew up, and worked with produce in retail and wholesale before starting his own business. Bridges Organic works with about 130 midsize farms that are too big to sell just through farmers markets and not big enough to employ a dedicated sales person.

“My primary obligation is to work for the growers,” he said. He sees himself as the growers’ agent “maximizing the sale of all produce and the returns.” He sells to wholesalers, chain stores, CSAs, prepared meal schemes (such as Blue Apron), processors and occasionally individual buyers, like the one from Boston who needed fingerling potatoes, which weren’t in season in the Northeast but were available in Oregon.

“When people at a dinner party ask me what I do, I compare my job with that of a talent agent in Hollywood,” said Johnson. “We match the right grower with the right sale.”

Bridges Organic specializes in crops that growers in the region do particularly well — 30 apple and pear varieties, summer fruit, potatoes and some row crops. For year-round supply, he works with partners in the southern hemisphere, too. Essential skills for the job are communication, strategizing and crisis management — like last weekend when a truckload of cranberries got stuck on the Canadian side of the border because of missing paperwork. Johnson tried to reach a customs broker on what turned out to be a Canadian public holiday while informing a dozen different buyers that the cranberries would be two days late and pick-up times needed to be rearranged.

“Buyers want a steady and seamless supply stream,” he said. “The better we plan, the better we can sell.” In an ideal world, Bridges Organic would know ahead of time exactly what farmers are growing, but no amount of planning can make up for changes in market demands and the weather.

Unlike OGC, Bridges doesn’t buy from growers, but he charges a commission. And instead of owning warehouses and trucks, the company rents them as needed. But the core principle of any successful distributor is the same: constant communication and dialogue. Johnson doesn’t just relate detailed information about market trends such as acorn squashes are out or the demand for spaghetti squashes is growing. Being a farm consultant is part of his job, too. He knows the farmers, the specifics of soil and climate, and he keeps in touch with seed companies and nurseries about which varieties do well and where. Bridges Organic may even shoulder part of the upfront costs — such as providing seeds, drip irrigation tubes and boxes, and offer help with paperwork: completing a 60-page social accountability or health and safety document correctly can give a farmer access to a larger buyer and better sales. As for the future? Johnson is not looking to grow Bridges Organic, but he wants to seize opportunities when they come up.

“The relationship with our growers is based on trust,” he said, “and as that develops, the relationship evolves.”

Black River Produce

In 2016, Black River Produce, an Oregon Tilth-certified distributor in Vermont, took the opportunity to scale up while maintaining its independence under a new owner: Reinhart Foodservices, a large, independent Chicago-based distributor.

“Reinhart has very similar work ethics,” said Sean Buchanan, divisional president at Black River Produce. “They don’t sell what we sell, but they know that their customers want more local and organic produce. That opens new markets for us, and the opportunity to move more produce.”

“Give peas a chance” was the slogan on the van of Steve Birge and Mark Curran, the Black River Produce founders, when they picked up produce from local farmers for their tiny natural foods store. Gradually, local chefs and restaurateurs started placing orders. Birge and Curran bought a barn as a first warehouse (unaware of the resident racoon which developed a technique of sucking the meat out of bananas with the fruit visually intact).

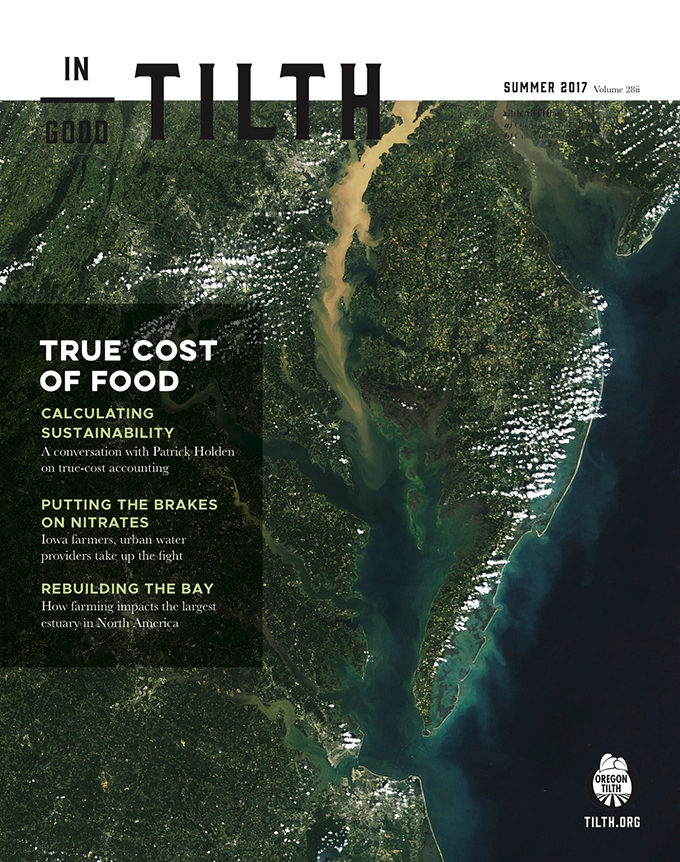

Today, Black River Produce operates a 60,000-square-foot warehouse in Proctorsville, Vermont, with six temperature- and humidity-controlled zones. Vermont’s growing season is short, and it rains frequently. Farms are small and diversified, with often 40 to 50 different crops to minimize the risks of crop failure. Farmers extend the season with greenhouses — for plug plants in spring and produce grown under glass in late fall and winter. Black River helps by promoting every opportunity to supply local produce that would otherwise have been sourced from California, Florida or Mexico. The company started with vegetables, but expanded into seafood, then artisan cheese and dairy and eventually dry goods and meat.

“We are a customer service company,” said Buchanan. “If there is a company that says we’d love artisanal cheese from Vermont, then that’s the challenge for us. We figure out how to do it.”

The traditional customers are retailers, natural food shops and restaurants. But institutional buyers like schools and hospitals make up the fastest growing sector. Buchanan hopes that coming under the Reinhart umbrella will allow Vermont produce to go to chain restaurants, too. And new markets in Boston and New York might be there for the taking.

“We have the produce with a story that matches,” said Buchanan. Black River Produce staff in Proctorsville may soon be packing individual orders of Vermont fresh produce, dairy and meat for customers in Boston and New York City.